There are different new technologies and innovations in the construction sector, one of which is precast concrete. However, precast concrete has been embraced, adopted, and used for many years in the commercial sector, with minimal application in the residential sector. Its minimal application in residential buildings is due to a lack of knowledge and information on its benefits and methodology, resulting in people opting to use traditional methodologies.

What are precast concrete wall panels?

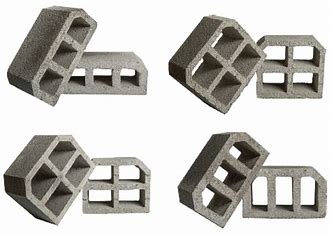

They are pre-made concrete products obtained by pouring concrete into a reinforced mold, followed by air-curing (Watering) for a specified period. The curing process allows concrete to gain strength and harden. Once ready, they are transported to the site assembled to make walls. They are used for both exterior walls.

How do you build with these panels?

Just like building with any other material, you need to follow all construction procedures, including obtaining the necessary permits, planning and coordinating with other construction trades, and site evaluation and preparation. Wall panels are installed in slabs which can be typical or a precast slab.

The next step is to install the wall panels. The first panel should be positioned at a designated corner of the building to determine the starting point of the wall. The second and other succeeding panels should be installed while validating the proper alignment.

For slimmer panels, it is important to use a levelled mortar or a C channel. A C channel is a mild steel section rolled into a C that restrains the panels in place both at the top and bottom and secures them together adding more stability to the walls.

Panels need to be pressed together to achieve a secure joint and bolster structural integrity. Waterproof sealant is then administered uniformly to the joints. The most commonly used in Kenya is high grade waterproof filler over a gypsum tape.

Do they require a special foundation?

Precast wall panels integrate well with normal foundations. Some have the advantage of being light and therefore foundations can be designed to adapt to their weight if required.

Are they durable?

One of the advantages of precast wall panels is that they are long-lasting. The durability parameter comes from the concrete material. The wall panels are molded with sand, gravel, and cement. When these materials are mixed with water, they form a matrix bond with high compressive strength, known as concrete. Concrete strength increases with time which is not the case with other building materials since they are susceptible to rust, rot, or deterioration upon exposure to moisture.

Is it a cheaper construction method?

With precast wall panels, you need fewer workers for less time on site, leading to savings on labor costs and time. The exact savings depend on how large your construction project is. It’s impact on cost is especially felt in larger scale projects. It requires little ongoing maintenance and will last for many years. Important to note is the cost of transport of these materials to your site.

If your designs are simple and easy to integrate with the precast panel wall dimensions, that’s when the impacts of using these materials are better felt.

How are they finished?

They can take various finishes to their surface. The most important thing is that one must apply a fibre tape between the panel joints in order to apply the chosen finish on the walls. One can skim the whole wall, paint, plaster, apply rough cast etc. These options depend on what the required finish is. The cost of finishes can be lower depending on the type of finish you want as the panels do not require plaster which is the most common finish.

What are the advantages of using precast concrete panels?

1. Saves on costs and construction time.

2. They save on space by maximizing the floor space. They are only 90mm thick as opposed to 150mm walls hence creating half a foo

3. Fire safety – They are made from concrete, which is a good fire-resistant material.

4. Versatile – They can be designed to fit different designs.

5. Durable – Since they are made from concrete, they are stong and robust.

6. Can provide excellent insulation and energy efficiency

7. Soundproof – This is especially true for panels that are hollow or with insulation in the middle.

What are the disadvantages of using precast concrete panels?

Everything has a downside, and so do precast concrete panels too. They include:

1. Higher upfront costs: Compared to other building materials, concrete panels have a higher initial cost. However, the cost is slightly cheaper than that of stone blocks. With long lasting and low maintenance properties, the higher initial costs are compensated.

2. They are heavy and therefore require good technique or machinery to lift depending on the size. The process is, however, quicker and easier.

3. Higher transport costs: This will apply if your project is far from the source of the panels.

4. Hard to renovate: Panels give you a variety of options during design, but once the structure is built, it is hard to modify.

5. There are issues with improper installation: The jointing and sealing process is crucial during installation. Improper installation results in faulty connections, resulting in water damage and sometimes sound insulation issues. This explains the need for an expert during construction. It is also important to make sure that the panels are sufficiently protected from the rain (Roofing, weather guard paint etc.) in order to maintain optimum living conditions on the inside.

6. Where required to span long lengths or heights, more structural support must be provided.

Consider using precast concrete wall panels in your ongoing or next construction project, as they are robust, long lasting, and cost effective to install and maintain. The panels offer a variety of design options to enhance the aesthetic appeal of your building.

For more information Kindly contact us at emailjenganami@gmail.com. Jenganami, Jenga Easy.