Gone are the days where all new developments, ranging from residential to commercial used septic tanks to collect and semi treat their waste. These septic tanks, connected to soak pits, allowed sewage waste to be collected, solid waste being retained in the chamber for further breaking down and liquid waste and water was semi treated and let out into the soak pit.

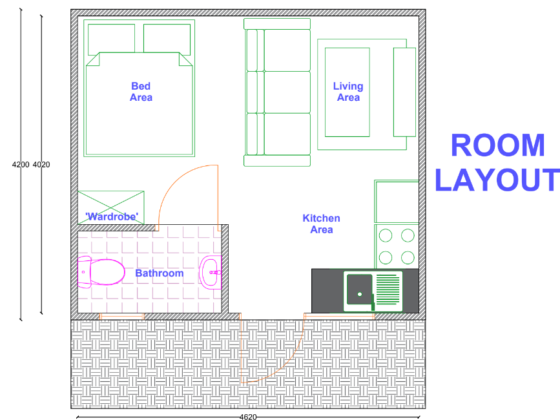

Biodigester systems are sized depending on the need of the household/development

The biodigester system, which has been gaining traction in Kenya utilises a different principle of dealing with waste (the displacement principle) and enzyme/bacteria that consumes organic matter in very little time. This means that the waste does not remain in the solid form for long. Once the bacteria feed on the waste, the product which is liquid can exit the system using the outlet.

When new waste enters the system, some of the water inside the system is displaced and the hungry bacteria within the biodigester go to feast on the new organic matter. This means that the biodigesters rarely get full and due to their reduced need to keep the waste in the system for a long time (retention time), the size of the unit is small. They usually come in rectangular and circular shapes with the walls being cast from concrete as opposed to the septic system of building using stones.

Biodigesters are heavily reliant on the soak pit/French drain and therefore this feature must work seamlessly for the system to function well. A soak pit is generally a hole filled with large chunks of stone where the waste from the system drains into. A French drain is used where the water level is high creating a stone filled trench used for the same purpose. One must always confirm the soaking away ability of the soil to ensure the system works well.

When you need to serve a large group of people, the biodigester can be redesigned to increase the number of chambers in order to allow for more retention time within the system and allow for the solid waste to settle easily.

This leads to some of the advantages of this system as the following.

1. Requires less space for construction

2. Requires less materials hence cheaper

3. Can be adapted to the needs of different people with sizes ranging from 1 m cubic to 3 m cubic. The cost ranges from Ksh. 80,000 (650 USD) – Ksh. 200,000 (1,550 USD), depending on the contractor

4.It requires little maintenance and no exhaustion as all the solid waste is broken down.

Soak pits are crucial for biodigester systems

Disadvantages of this system include:

1. Care must be taken to ensure the correct enzyme/bacteria is fed into the system. Feeding the wrong bacteria will lead to the system filling up with solid matter and requiring evacuation

2. When building in black cotton areas, ensure the walls of the system are protected from the soil pressure from expansion of the soil during wet weather to avoid collapse. This may involve lining the pit with a hardcore (stones) to create a buffer between the structure and the soil.

3. The inspection holes are very small (pipe size).

4. The system works better when waste from the toilet is separated from the Kitchen and bathroom waste. Especially in areas that generate high waste.

5. For large numbers, care must be taken to ensure the waste gets enough time to settle.

Always ensure that the system does not allow rain water inside to maintain the good working condition. Consult professionals when installing these systems for your home.

I hope this read has been helpful. Build wisely.