What are hollow pot slabs?

Hollow pot slabs are suspended slabs that are designed to incorporate the use of hollow pot blocks as slab fillers to reduce the total weight of the slab while still maintaining the structural integrity of the slab.

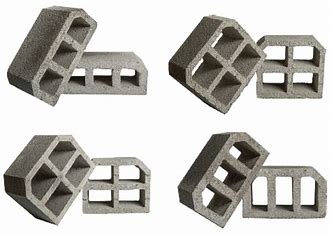

Technical information on hollow pots/ Hollow pot measurements

Hollow pots are manufactured using cement, sand/smooth aggregate and water mix that is pressed into moulds and set to dry. They are basically concrete blocks with a different shape. They are mostly 390 mm – 400 mm by 200mm (On plan), but the depth varies from 150mm, 165mm and even 200mm. They can also be deeper. What determines the required size are the technical details provided by your structural engineer.

How hollow pots are used on site

These hollow pot blocks are arranged on the slab formwork which has been lined with a membrane according to the technical drawings provided by the S.E. They are typically integrated with ribs (rebar) after each column of blocks. Then an additional welded mesh is placed on top of the bed of blocks and then the whole structure concreted together to create one solid component.

What are the benefits of using slabs?

Hollow pot slabs are designed to reduce the weight of the slab. A typical solid concrete slab is definitely heavy. Hollow pot slabs work by introducing hollow pot blocks to the structure of the slab and therefore reducing the total weight since the slab essentially has hollow elements in it. This means that the structure will benefit in the following ways:

1. The amount of concrete required to attain the total depth of the slab will be reduced. Hence saving on cost of concreting.

2. The structure itself will be lighter which means one can reduce the specification required in the support system (Columns and bases). This saves money too as less steel is often used.

What are the downsides?

1. While it’s common for people to use hands on experience to pour simple slabs, it is important that hollow pot slabs are designed by a qualified structural engineer to ensure the soundness of the structure,

2. The hollow pot blocks often leave a surface that is not uniform on the soffit of the cast slab (underside) and therefore might require additional rendering to make it even if n even surface is required.

I hope this read has been useful. Build wisely!