A concrete grade is an indication of the strength that a concrete attains after maturity. In most cases the strength is measured at 28 days since concrete usually achieves around 99% of its strength by this time despite the type of mix.

Concrete grades are measured by conducting compressive tests on cubes of 150mm by 150mm by 150mm that have been curing for 28 days for optimum strength. To show concrete strength it depends on whether you use M(Mix indicator based on cube tests) or C(Mix indicator based on Cylindrical tests).

M usually denotes the mix and the number next to it denotes the strength that is achieved by a cube after 28 days of curing in N/mm2.

Uses of different Grades.

Anything below M20 is not considered structural concrete and therefore should not be used for intense structural uses unless it is carrying very little weight. Therefore, M20, is used for outdoor slabs, like sheds, patios, garages, especially as slabs on Ground, where it just transfers the weight to the ground directly..

M15 is generally used as blinding to concrete structures. Blinding is concrete that is used to level out the ground and create a base on which the actual concrete foundation is put. It can also be used to make Cabro blocks that don’t carry too much weight or blocks that are only to be used for partitions and not load carrying walls.

M25 – M35 Are typically used for structural purposes of small to medium housing. Note that in housing, the columns and bases(members that take a lot of compressive load), require high strength concrete. This is usually based on the prescription by the structural engineer.

M45-M60 – These are used for construction that requires very high strength concrete to make it work. They are commonly used to make precast structures for bridges and highways that carry a lot of load. The cement used to achieve this mix is a little different and needs supervision during placing and curing to ensure that quality of output is optimal.

It can also be used when high initial strength is required quickly such as in the repair of roads, or to hold up posts in fence construction.

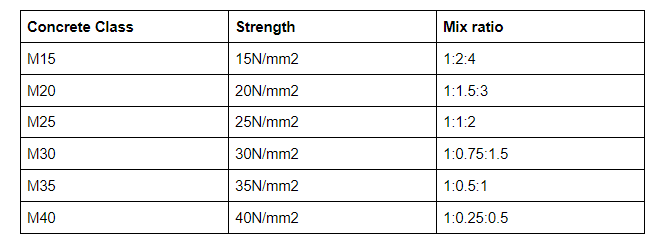

Mix design is the ration with which water, cement, smooth aggregate (sand) and coarse aggregate(ballast) are mixed to provide the required concrete strength. They are usually batched in terms of volume or weight depending on availability of measure apparatus. For those building in Kenya, here are the mix ratios for common strength classes.

Here is a table denoting the Mix ratios of common concrete grades in the industry. It may vary with local standards, depending on the country of use.

Note that in Kenya, the mix design below is used based on local materials. Ie, Riversand, 20 mm sized aggregate and local Grade cement. This is because the smooth aggregate used is naturally available sand that forms strong concrete.

I hope that this read has been useful. Build wisely!